BR Sales being one of the leading service providers in industry we are engaged in providing high quality Industrial Project Consultancy services. Our experts interact with the clients and analyze their needs and offer services accordingly. We are offering Consultancy for Electronic Products and Ceramic Lined Equipment’s.

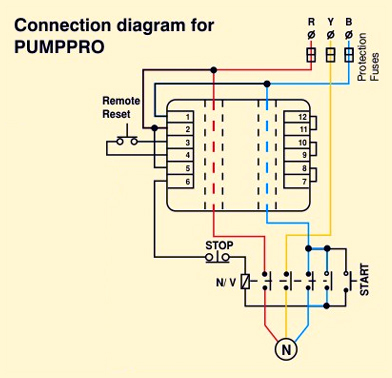

Pumppro unit which is basically current sensing single phasing which can protect the submersible pumps against overloading, dry running, unbalanced currents, reverse phasing and single phasing up to motor terminal. As it is prodless, it eliminates external sensing prod. With the use of this unit. Bimetallic overload relays and single phasing preventers are not required.

Thus it offers comprehensive protection to submersible pumps and also saves cost by eliminating thermal overload relay, separate single phasing preventer, water level guard and cable for sensor. It is available up to 200 amps. Green led indicates spp healthy condition and red led indicates overloading condition. Auto / manual / remote reset provision is provided for overloading. It weighs 750 grams approx. And measures 140 x 100 x 95mm (overall). Mounting dimensions is 129 x 74mm.

PUMPPRO is a negative sequence current sensing SPP with single phasing, overload(over current) and dry run (under current) protections. Overload setting needs to be set as per current rating of the pump & Dry Run setting needs to be as per no load current of pump. PUMPPRO offers dry run protection without need of the prod.

| System Voltage | 415V +/- 20%, 3, 50 Hz. |

| Auxiiary Supply | 415V/230/110 V AC, 50 Hz. |

| Output contact rating | 1 C/O potential free,6A resistive at 230V or 1 A at 415V at 0.5 P.F. |

| Trip Setting | |

| Unbalanced | 50% of rated maximum current. |

| Dry Run(under current) | Variable between 50-75% at set overload current |

| Overload | 120% of the full load current for that adjustable potentiometer provided on the unit. |

| Trip Time Delay | |

| For Single Phasing | 4 to 7 Seconds |

| Reverse | |

| Phasing | |

| Dry Run | 15-18 Seconds |

| For Overload | As per inverse time current characteristics(2sec. standard & 6/10sec. on request) |

| Reset | Auto/Manual/Remote for each SPP,O/L & Dry Run selection |

| Power Consumption | 3 VA |

| Recommended Wiring | 1.0 Sq.mm |

| H.V Test | 2 KV AC, 50 Hz for 1 minute between mounting plate and any terminal. |

| Fail Safe | Relay is energised in healthy conditions and trips in faulty conditions. |

| Humidity | Up to 95% RH |

| Enclosure | High impact polystyrene modulded with nylon moulded connection strip. |

| Life Expectancy | 0.5*100000 operations |

| Indication | ON,SPP FAULTY, OVERLOAD, DRY RUN |

| Dimension | |

| Overall | 140 X 100 X 95 mm |

| Mounting | 129 X 74 mm. |

| CT Dimension | |

| Inbuilt | 16 mm ID |

| Separate | 31 mm ID |

| Weight | 750 gms(approx.) |